Products

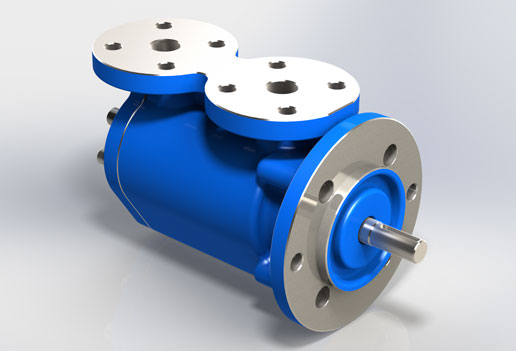

SPF type three-spindle screw pump

●Use

For the delivery of fuel oils, lube oils, hydraulic oils or other lubricating liquids. The delivery media must not contain any abrasive particles nor chemically attack the pump materials.

●Main fields of application

SPF pumps operate as transfer, booster and burner operation pumps in fuel oil engineering, as transfer and

filling pumps in tank farms as well as lube-oil pumps in any industrial branches. They are moreover used for

pressure generation in oil-hydraulic plants of all kinds.

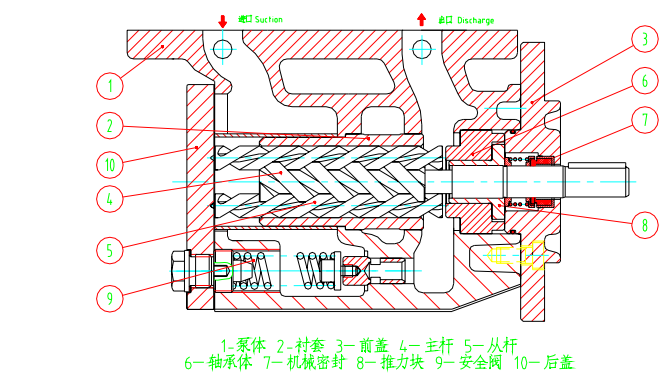

●Design

Self –priming three-screw type of pump with internal bearing. The hardened and ground screws run in an exchangeable casing insert.

The driving screw is hydraulically balanced. The axial thrust of the working screw is absorbed by the endside pump cover their drive is hydraulic. The thread flanks merely transmit the torque resulting from the liquid friction. Thus, the thread flanks are practically stress-free and not subject to any wear. All sliding parts are lubricated by the delivery medium being within the range of full liquid friction.

The radial and axial bearing of the driving screw is by the balancing piston guided in the bearing ring. Simultaneously, the gap between balancing piston and bearing rings separates the pressure chamber from the sealing chamber. A maintenance-free mechanical seal is provided as the shaft sealing.

Sealing chamber and suction chamber are interconnected by way of a return gallery. Thus, independently of the delivery pressure at the shaft sealing, only the suction pressure becomes effective.

Complete units being supplied, the connection pump/driving motor is by a pump connector with bracket(size 20) or by a wall/foot bracket resp. (size 40)

●Main feature

1. Operation

Owing to a special profiling of the thread flanks, the three screws from sealed chambers the contents of which

are axially and completely continously shifted from the suction to the pump side of the pump as the screws turn.

There will be no turbulence in spite of the screw rotation. The constant chamber volume excludes squeezing.

2. Noise/pulsation

The structural design and operation of the screw pump ensure a very low noise level and almost pulsation-free

delivery.

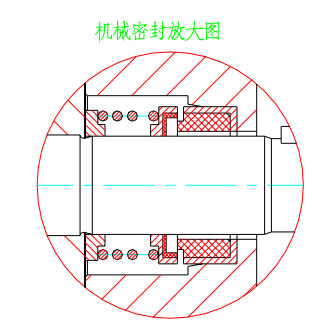

3. Shaft sealing

By means of a maintenance - free mechanical seal of the unbalanced type.

Material design:

Rotary seal ring Hard carbon metal -- impregnated

Stationary seal ring Cast steel

Bellows,gasket viton

Spring High – quality steel

Metal parts Steel phosphatized

4. Temperature and pressure limits

Admissible temperature 150 ℃

Admissible delivery pressure 4.0 MPa

Admissible supply pressure 1.0 MPa

5. Pressure relief valves

As an overload protection, installed in each pump is a pressure relief valve

6. Flanges/Connections

Flanges

Suction side:PN16DIN2533(GB2555-81)

Delivery side:PN40DIN2535(GB2555-81)

7. Installation

SPF pumps may be mounted in any position. For safety purposes, the arrangement with “motor downwards” is

not admissible.

8. Drive/Coupling

By way of an intermediate connector, electric motors of the most varied designs or other prime movers can be

connected with the pump Normally, the following are provided;

Surface – cooled three – phase squirrel – cage motor, enclosre IP44 according to IEC Standards.

Class B insulation, performances and main dimensions according to Y series motor.

Motorsrated for 50HZ may without any change also be operated form 60HZ supply systems.

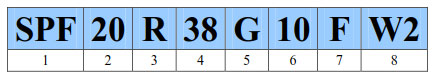

●Model code

① Series

② size

L=theoretica delivery flow at 1450 r/min and 46°pitch angle

③ Direction of screwpitch (R=right – hand ,L=left – hand )

④ Angle of screwpitch(degrees)

⑤ Type of bearing

⑥ Shaft sealing by mechanical seal

⑦ Model with filter

⑧ Material

2016/03/18

2016/03/18- Last:SMtype three-spindle screw pump

- Next:3G series screw spindle pumps