Products

SN type three-spindle screw pump

Main Feature

- SN three-spindle screw pump is of self priming

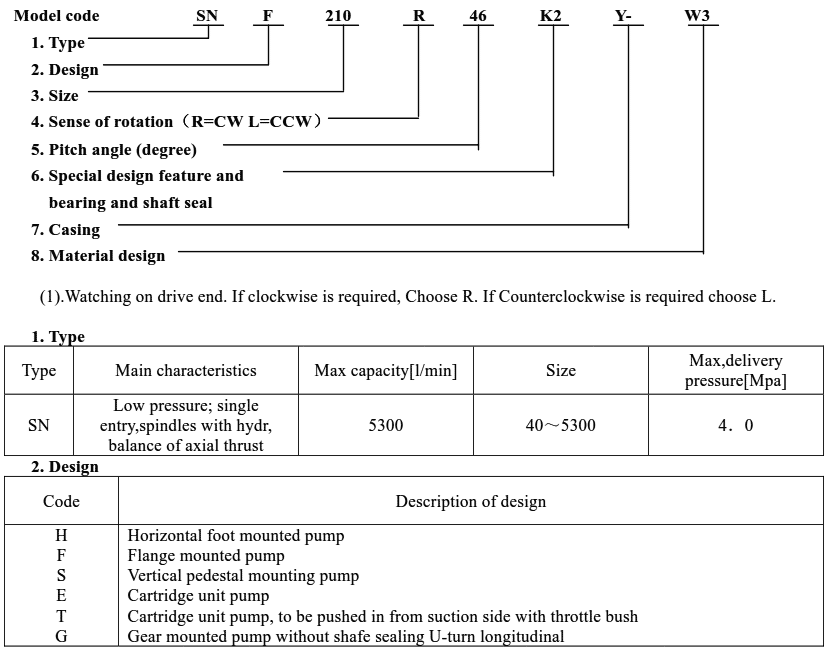

- Because of the unit assembly system every pump can be supplied as cartridge pump for foot-,flange-or wall mounting, in pedestal-,bracket-or submersible design.

- According to the delivery medium heated or cooled designs are also available.

Usage

·For the handling of oil and medium with lubricating pvoperties.

Application

·In heating techniqzzues as fuel oil and medium with lubricating pvoperties.

·In the engineering industry as hydraulic-,and telemotor pumps.

·In the chemical and food industry as cargo-,transfer or supply pumps.

·In the marine field as transfer-,booster-,fuel oil pumps as well for ship hydraulics.

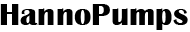

Structure

U12.1 Structure

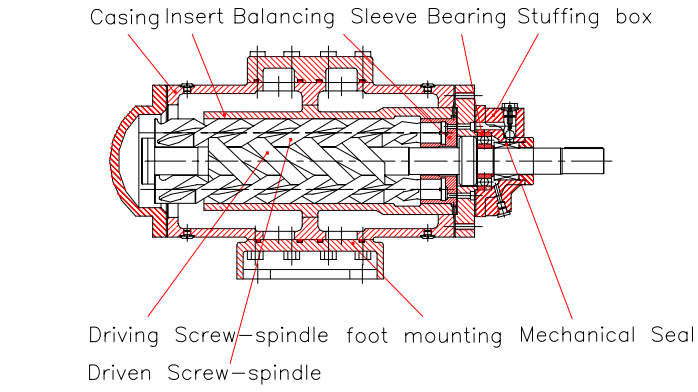

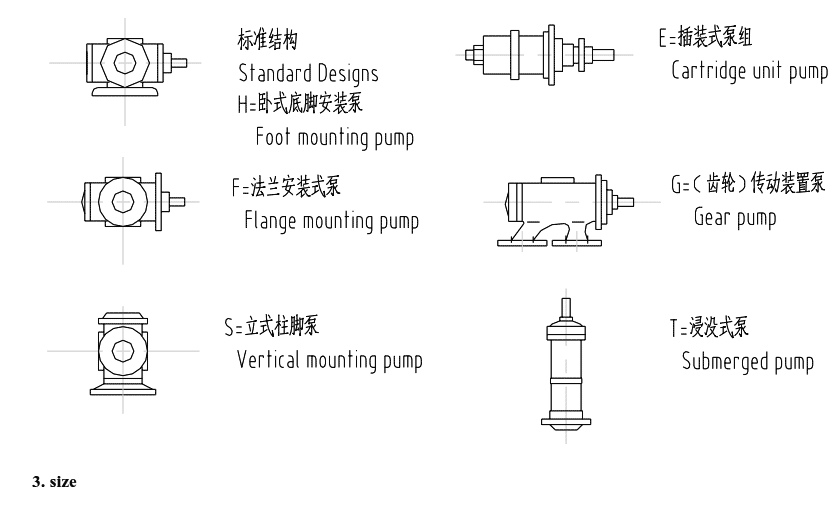

Model code of screw pump of SN series

Step of selecting SN series pump

When chose the three screw pump, you must know the suing condition of the pump, not only the operating data, such as capacity, pressure but also the specific property and corrosiveness of the medium. At the same time you must know the gas content of the medium, the solid size and the temperature, viscosity of the medium.

The user can fill the data sheet of the pump.

The manufacture will choose the pump for you.

1. Confirm the pump speed: (the max speed of the SN series pump is <6000rpm)

A. The speed should be chosen according to the transferring medium’s viscosity and the pump’s type speed limits. Normally high viscosity medium should chose low speed, low viscosity medium should chose high speed.

For big size pump (driving spindle outside diameter∮above 60mm), when viscosity V>20°E, the speed should be between 970-720rpm. When V>80°like viscose, the speed should be between 200-500rpm.

For the small size pump (the outside diameter∮under 60mm). When V>20°E, the speed should be between 1450-970rpm. When V>80°E, the speed should be between 300-600rpm.

B. The high speed of the pump is and the high friction power will get. So the pump wears badly and the service life will be shorten. If the transferring medium’s lubrication is not good or the medium has some micro foreign matter, the speed should be 1450rpm.

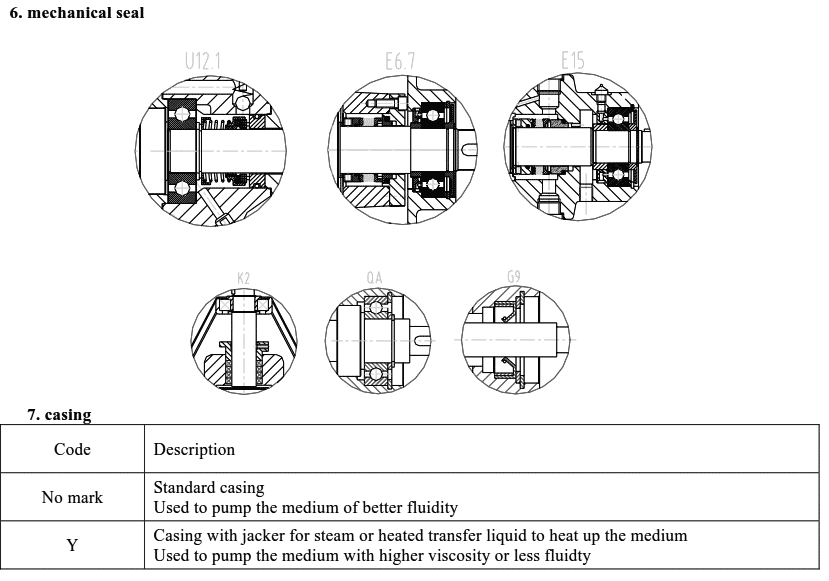

2. Choose the structure of the pump

Chose the structure of the pump is according to the operating and installing environment. Chose suitable installing structure should adhere to the following principle.

A. Transfer medium with lubrication, temperature T<80℃, chose internal ball bearing type pump.

B. Transfer medium with bad lubrication, temperature T>80℃, chose external ball bearing type pump.

C. Transfer medium with bad flow, high viscosity the medium needs keep warm and heating. Chose casing with jacket type pump.

D. Transfer high temperature medium, chose high temperature-resistant and parts cool type pump.

E. About the suction ability please check the data sheet of the pump.(catalog)

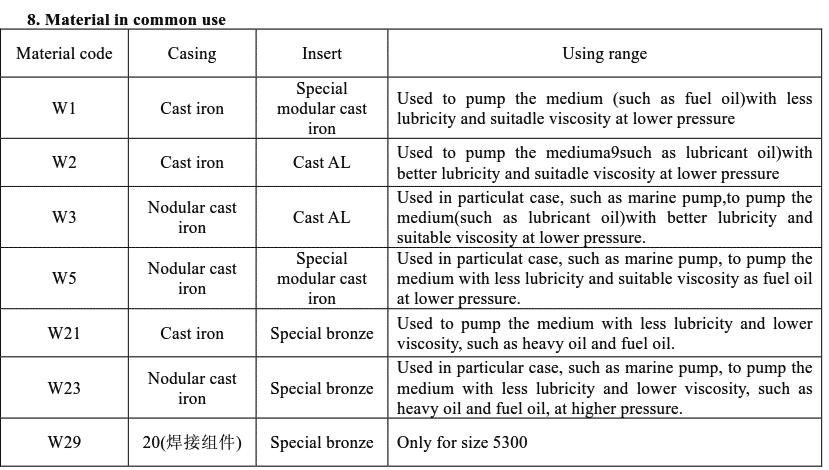

3. The pump material code please check the data sheet of the pump (catalog).

4. NPSHr of the pump

Reduce the speed and heating the medium reduce the viscosity can get high NPSHr. Please see the NPSHr sheet.

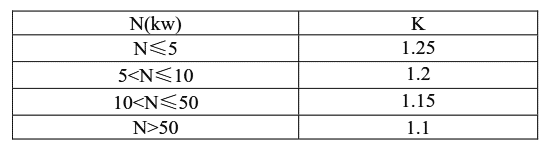

5. Select motor for the pump.

After chose the pump, please check the data sheet. You will get the shaft power N. The shaft power N add dump power. This is the basis for selecting motor. Normally motor power Nm is not less than the shaft power N. Shaft power N times dump power coefficient K. You can get Nm≥K•N. The K value please check the following sheet.

6. In order to let the clean medium to the pump, it is better to fix a filter on the suction part. The filter should be 40-80 mesh.

In addition, some times you can’t find the exact pump data you needed. This is because our pump function data in the data sheet under the condition of special viscosity and speed. In this case you should adhere to the following principle. If you want to have the exact data, it is better to seek advice from our engineer.

A. Three screw pump’s capacity and pressure at the same viscosity, speed will be rectilinear relation, the high pressure and the small capacity.

B. Same viscosity and pressure the pump’s capacity and speed is direct ratio.

C. Same speed and viscosity, the shaft power and pressure is direct ratio.

D. Same viscosity and pressure, the shaft power and speed is direct ratio.

If the viscosity is higher, the capacity and shaft power will be increased. In this case it is better to seek advice from our engineer.

Example: At normal atmospheric temperature to transfer V=75cst lub-oil, Q=11.5m3/h, P=1.0MPa

According to the above data check the pump catalog to chose SNH210R46U12.1.

The pump data is : Q=203l/min=12.18m3/h, p=1.0MPa, n=1450rpm, N=4.24kw. Chose the motor according to the shaft power.

Check the dump power coefficient K=1.25. The motor power Nm= K•N=1.25*4.24=5.3kw.

Check the motor catalog Y132S-4 motor power is 5.5kw.

So SNH210R46U12.1-Y132S-4 is in keeping with the requirement.

2016/03/18

2016/03/18- Last:W·kse twin screw pump

- Next:SMtype three-spindle screw pump